Car body primer: defects, causes, prevention and remedies

See the products concernedPaint primer for bodywork: what is it used for?

Paint primer is one of the essential products in a bodywork workshop. Used when preparing the bodywork surface, the primer is an undercoat designed to increase the adhesion of the surface before applying the paint. It is also used for finishing. Paint primer is very practical, because it can be adapted to any type of car paint. Carross offers you a wide choice of automotive primers to meet all your needs, with products from Nexa Autocolor, Standox, Spies Hecker, Sikkens, RM, PPG, Lesonal, Lechler, Maxmeyer, Glasurit, Cromax, De Beer and 4CR, Mobihel and others.

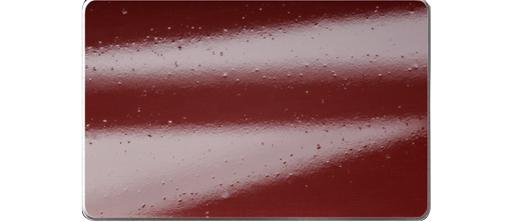

Blistering

Description

The presence of blisters of varying sizes on the surface, perceptible to the touch. The blisters may appear between the different layers of the paint film or under the primer.

Causes

- Too short evaporation time between coats of water-based products.

- Excessive humidity in the ambient air.

- Condensation due to temperature variations.

- Insufficient insulation of polyesters.

- Sanding water too hard.

- Dirty compressed air.

- Coat thicknesses too great.

- Sanding water residues in corners, on edges, in rebates and mouldings and under decorative strips.

- Dried salt residues.

- Pollution.

Preventive measures

- Before application, dismantle components if possible and clean in accordance with instructions.

- Do not allow sanding residues to dry, wipe them up.

- Always remove exterior trim.

- Prevent the formation of condensation and maintain a constant temperature and humidity.

- Observe the primer thickness recommended by the manufacturer.

- Respect the intermediate evaporation times of the products.

- Dry thoroughly by blowing air.

- Check the air supply equipment regularly. Compressed air must be clean and dry.

Remedies

- Sand the contaminated primer down to the sheet and reapply in accordance with the manufacturer's instructions, taking into account the recommendations given above.

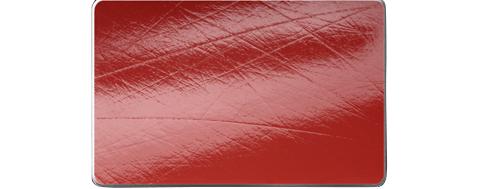

Sanding marks on the bodywork

Description

Sanding marks on the surface under the paint film. Sanding marks in the substrate appear as scratches in the surface of the repair lacquer.

Causes

Sanding of the old primer with too coarse grit sandpaper.

Insufficient drying of the primer before applying the lacquer. Sanding scratches become clearly visible due to swelling of the undercoat and burying of the lacquer (loss of gloss) after the lacquer has dried.

Viscosity too low or insufficient thickness of topcoat.

Preventive measures

- Prepare the substrate using sanding paper with the grit size specified by the primer manufacturer. As a general rule, sand scratches with fine abrasive paper.

- Seal the sanded areas well with primer.

- Dry the primer thoroughly in accordance with the data sheet.

- Observe the recommended viscosity and thickness of the finishing paints.

Remedies

- If the problem is not very visible, try sanding the affected area with fine paper and buffing. If the problem is more serious, sand down to the bare sheet and reapply the primer.

Poor adhesion to the bodywork

Description

The primer (or undercoat) has separated from the substrate.

Causes

- Poorly prepared substrate with grease residues, fingerprints, dust.

- Use of unsuitable materials for certain body panels.

- Use of unsuitable Thinner.

- Moisture on the substrate

Preventive measures

- Degrease the substrate to remove any contaminants and dirt that reduce the surface tension of the substrate.

- Prepare the substrate for painting. Sanding and sandblasting improve adhesion by increasing the surface area available for contact.

- Check the compatibility of the substrate and primer.

- Use the prescribed Thinner.

- Avoid using products from different manufacturers.

Cracks

Description

Presence of more or less tiny cracks and deformation of the film (swelling, extra thickness).

Causes

Tint applied to a primer film or undercoat that is still damp or too thick: too short evaporation time.

Preventive measures

- Observe recommended drying times.

- Observe recommended coat thicknesses.

Remedies

Sand the cracked surface to a smooth, sound surface and reapply the primer in accordance with the manufacturer's recommendations.

Pores on body primer

Description

Presence of small cavities on the surface of the primer coat.

Causes

Incorrect application and drying of the primer, which may result from :

- Application of a primer with too high a viscosity (low-quality thinners).

- Application of too thick a primer.

- Using Hardeners that are too fast during hot periods.

- Drying primer in direct sunlight.

Preventive measures

- Apply the primer in the recommended thicknesses and follow the evaporation and drying times indicated on the technical data sheet.

- Always check the viscosity of the product before application.

- Use the recommended Hardeners according to ambient temperatures.

- Dry inside the workshop or in a place sheltered from direct sunlight.

Remedies

Once completely dry, sand and reapply the primer.