Spare parts for bodywork spray guns

Spare parts for paint spray guns

-

027243Plastic bucket QCC0.6L

027243Plastic bucket QCC0.6L -

1006916Satajet 5000 PHASER projector kitRP - Nozzle 1.3mm

1006916Satajet 5000 PHASER projector kitRP - Nozzle 1.3mm -

120675Plastic bucket QCC0,3L

120675Plastic bucket QCC0,3L -

128470Non-QCC plastic bucket0.3L for Minijet 1 to 4 and minijet3000B

128470Non-QCC plastic bucket0.3L for Minijet 1 to 4 and minijet3000B -

137729QCC aluminium bucket0.75L

137729QCC aluminium bucket0.75L -

140582Pack of 5 nozzle sealsof Paint Satajet 1000, jet 100

140582Pack of 5 nozzle sealsof Paint Satajet 1000, jet 100 -

145268Satajet 100 projector kitRP - Nozzle 1.8mm

145268Satajet 100 projector kitRP - Nozzle 1.8mm -

210252Satajet 5000 projector kitRP - Nozzle 1.1mm

210252Satajet 5000 projector kitRP - Nozzle 1.1mm -

210963Satajet 5000 projector kitHvlp - 1.2mm Nozzle

210963Satajet 5000 projector kitHvlp - 1.2mm Nozzle -

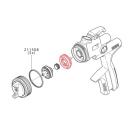

211508Air cap gasketSatajet 5000 - ( X5 )

211508Air cap gasketSatajet 5000 - ( X5 ) -

211540Sata ADAM 2 completefor Satajet 5000/5500

211540Sata ADAM 2 completefor Satajet 5000/5500 -

211565Adam2 supportfor Satajet 5000/5500

211565Adam2 supportfor Satajet 5000/5500 -

213025Jet settingSatajet 5000

213025Jet settingSatajet 5000 -

27771Air micrometer withPressure gauge

27771Air micrometer withPressure gauge -

Project 4000Projector kit forSatajet 4000

Project 4000Projector kit forSatajet 4000

︾

Spare parts for body paint spray guns and Clearcoats

Spare parts for paint and varnish spray guns play a crucial role in maintaining the optimum performance of these tools and helping to achieve professional paint finishes. Among these parts, filters, rigid buckets, pressure gauges and gun supports are of particular importance. Here's an overview of the importance of each of these spare parts:

Paint gun filters:

Filters are essential to prevent dirt particles, impurities and residues from contaminating the paint. They ensure a clean application by avoiding any risk of clogging the gun and guarantee a smooth, even finish. Filters are usually located at the gun inlet and can also be used in the cup.

Rigid buckets for paint spray guns :

Rigid buckets are the reservoirs into which paint is poured before being sprayed. They ensure a constant supply of paint during application. A quality cup, often made of stainless steel or durable plastic, ensures chemical compatibility with the paint used and is resistant to solvents. The design of the cup can also facilitate cleaning.

Pressure gauges for paint spray guns :

Pressure gauges are devices that measure the air pressure in the gun system. Maintaining the correct air pressure is essential for optimum paint spraying. Pressure gauges allow users to monitor and adjust pressure in real time, ensuring accurate and consistent application.

Paint gun holders :

Spray gun holders are used to hang or rest the spray gun when not in use. They help prevent paint contamination by avoiding contact with unwanted surfaces. As well as providing a safe place to store the gun, some gun holders can also offer additional features such as hooks for cables or storage space for accessories.

By investing in quality spare parts and maintaining them on a regular basis, Paint gun users can extend the life of their tools, reduce the cost of maintenance and improve the quality of their paint.By investing in quality spare parts and maintaining them regularly, users of paint spray guns can extend the life of their tools, reduce downtime due to mechanical problems, and guarantee consistent quality of paint jobs. Periodic replacement of filters, buckets, pressure gauges and holders is a recommended practice to ensure reliable operation and professional results.

How to use a plastic cup for a paint spray gun :

Using a plastic paint gun cup is an important step in ensuring efficient and accurate paint application. Here's a step-by-step guide on how to use a plastic cup with a paint gun:

1. Preparing the cup:

Make sure the plastic cup is clean and free from any traces of previous paint. If necessary, clean it thoroughly to avoid contamination of the new paint.

2. Choice of cup size :

Some paint spray guns can be fitted with different cup sizes to suit the amount of paint required. Choose the cup size according to the amount of paint you plan to use.

3. Preparing the paint :

Shake the paint well to ensure even pigment distribution. If necessary, thin the paint according to the manufacturer's recommendations and make sure it is the right consistency for spraying.

4. Attaching the cup to the gun :

Make sure the gun is switched off and the air pressure is cut off. Attach the plastic cup to the gun by aligning the notches and turning clockwise until secure.

5. Adjusting the air and paint flow :

Turn on the gun and adjust the air pressure according to the paint manufacturer's recommendations. Also adjust the air flow and paint volume according to your specific needs and the characteristics of your gun.

6. Spray test :

Before starting to paint the actual surface, carry out a spray test on a piece of cardboard or paper to ensure that the gun is correctly adjusted and that the paint is sprayed evenly.

7. Applying the paint :

Now that the gun is set correctly, start applying the paint to the surface to be painted. Keep the gun at an appropriate distance from the surface and use even strokes to achieve even coverage.

8. Replenishing the paint :

When the paint level in the cup decreases, stop, turn off the air pressure, and replenish the cup with paint if necessary. Make sure you follow the safety instructions when refilling.

9. Cleaning the cup :

After finishing the application, turn off the gun, cut off the air pressure, and remove the cup. Thoroughly clean the plastic cup to avoid contamination during future use.

By following these steps, you can effectively use a plastic cup with your paint spray gun, ensuring a precise and professional application of paint to the bodywork.